Introduction to metal cutting techniques

Thermal cutting of metal uses concentrated heat to sever the metal. Water jetting uses a jet of water (+ abrasive) under high pressure to cut the material.

We cut your test pieces without obligation and are happy to give you more information about our special training and service.

Contact usThermal cutting of metal uses concentrated heat to sever the metal. Water jetting uses a jet of water (+ abrasive) under high pressure to cut the material.

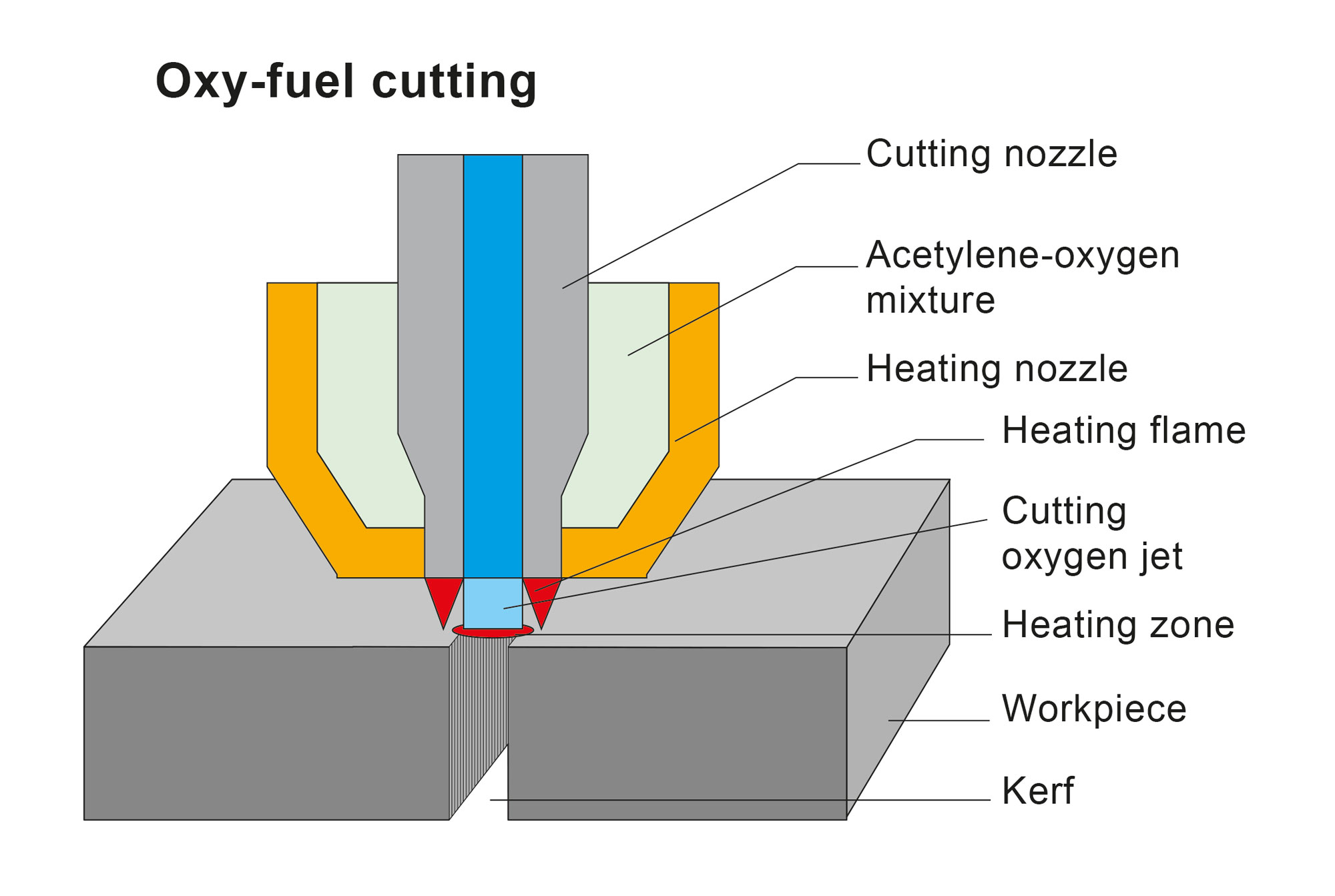

Warmth is produced by a flame of oxygen and a fuel gas (acetylene or propane). This is the oldest method and is used for steel in thicknesses range from 5 mm tot 300 mm. This method can only be used when cutting steel (not voor stainless steel). This is still the best choice for cutting thicknesses greater than 40 mm.

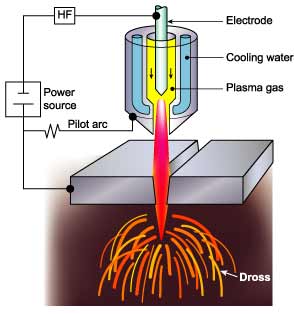

The heat is produced by turning gas to plasma (similar to lightning). This technique is employed for the cutting of material with thicknesses ranging from 0.5 mm to 50 mm. All conductive materials can be used. The cutting speed is very high which increases the productivity of this method.

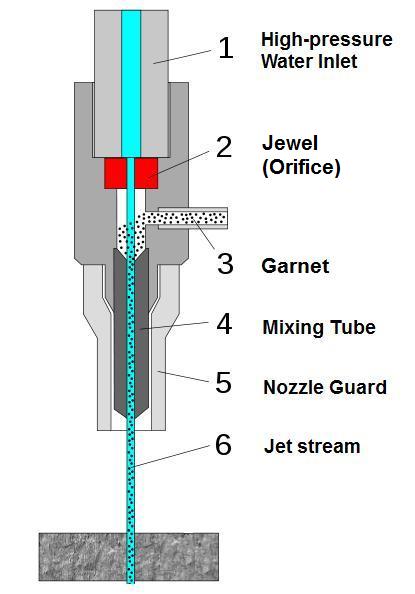

The material is cut with a thin water jet and, if needed, abrasive particles (sand). This technique can be used for all kinds of materials. The inclination angle is smaller than by plasma cutting but bigger than by laser cutting. The process is very slow and consequently only economically interesting after plasma and laser cutting. The downside for rust sensitive materials is that the work pieces have to be dried before stacking.

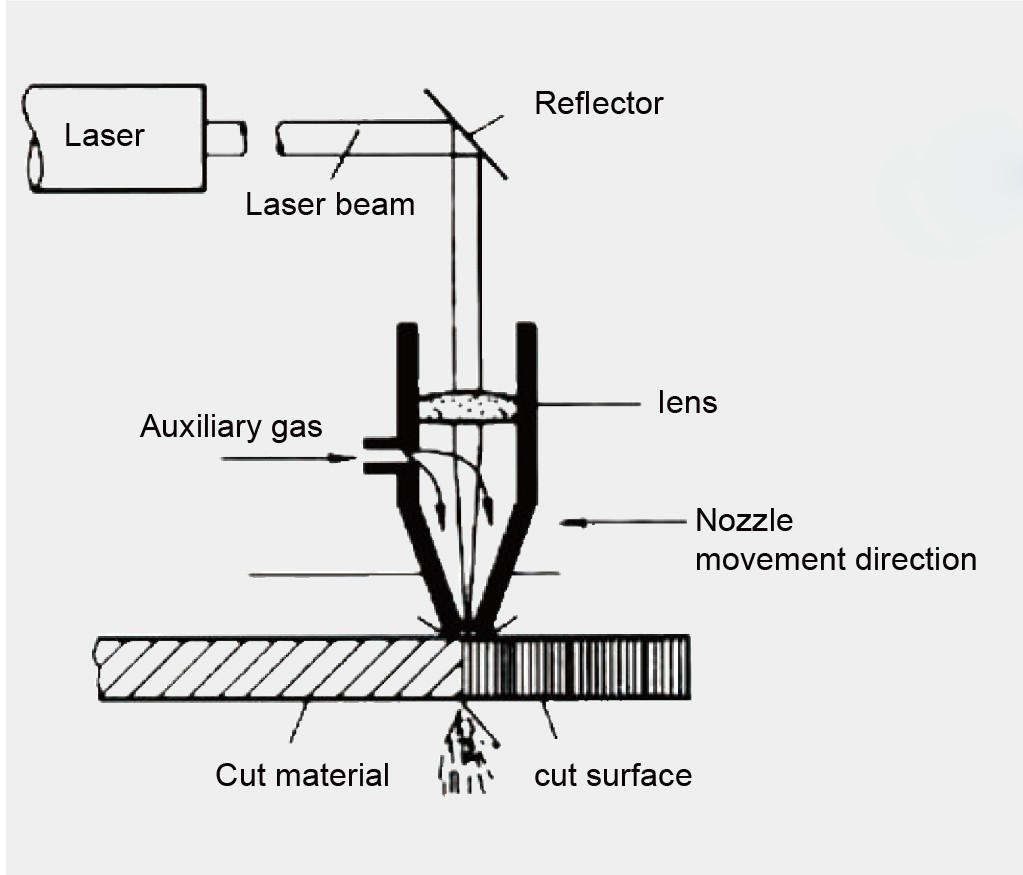

The heat source by laser cutting is concentrated light. The light is created in the laser source and send to the plate through mirrors or optical wires. This technique is used for steel thicknesses up to 30 mm. It is the most efficient by cutting thickness lower than 5 mm. By thicknesses higher than 5 mm they are swiftly overtaken by plasma cutting. The current fiber lasers have an energetic efficiency of approximately 30%.

Her you can read more about this technique: https://astratec.eu/plasma-cutting-machines/plasma-cutting-of-plates/

Contact us for a tailor made offer: https://astratec.eu/contact/

Or reach us here:

Contact us for a tailor-made offer: https://astratec.eu/contact/

Or reach us here: