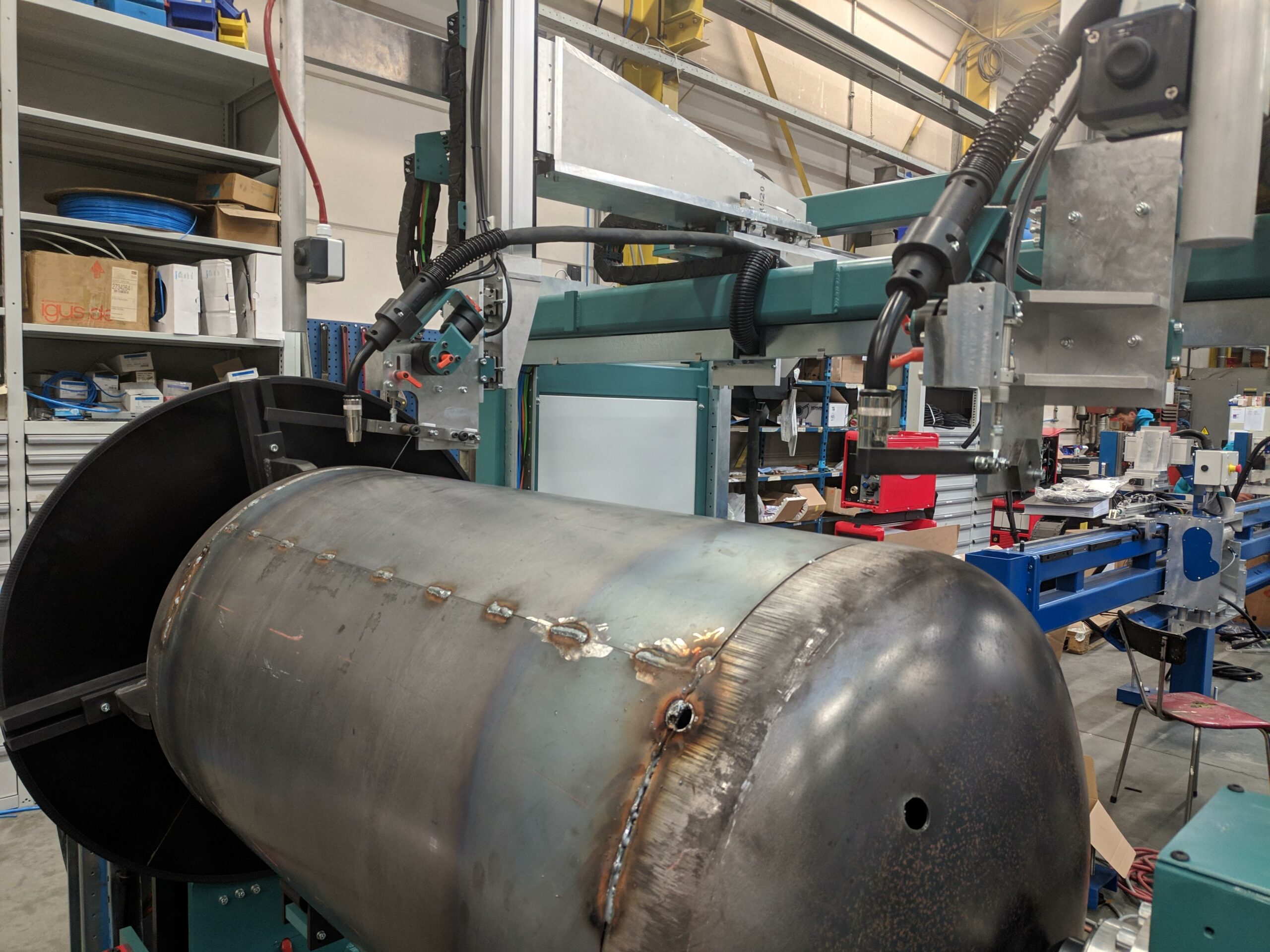

Welding automation for pressure vessels

Automation for MIG/MAG welding of steel pressure vessels.

Automation for MIG/MAG welding of steel pressure vessels.

This welding automation is used for the MIG/MAG welding of steel pressure vessels with diameters ranging from 195 mm to 800 mm. The vessels have lengths from 200 mm to 2654 mm and the largest vessel weighs 350 kilo’s.

The pressure tanks are moved on the machine by a lift bridge. Once placed the vessel is clamped and the welding movement begins. This movement is controlled by a servo motor.

The MIG/MAG welding torches are pneumatically lowered when the welding commences. The torches can be adjusted to perfection. After the welding process the vessel is released and moved to the correct height for rolling on the output table.

Astratec produced this machine for Lorivan.

Contact us for a tailor-made offer: https://astratec.be/contact/

Or reach us by: